Features:

Size 20mm Flanged

Mount Top and Bottom

Orientation The one unit can be easily changed to left or right

Body Bronze

Pressure 17 BAR

Temperature 0°C to 225°C

Flanged Bronze Water Level Gauge mount set which includes a Top and Bottom mount. Used on boilers as a sight level gauge. Made to AS 1271-2003 section 5 and includes self closing isolation ball in the event of rupture of glass (this will not do a full shut off as otherwise you would not be able to blow down the gauge glass, it is made as per the standards specifications for seat engagement). Standard with Graphite packing sleeves and stainless steel spindles. Compatible to AB12 Klinger and to suit 3/4" outside diameter glass (or smaller glass with different rubber cones). This set does not include the glass which needs to be ordered seperately and cut to required length. Utilising a graphite sleeve for the packing ensures a quick and easy renewal of the sleeve. Replacement spindles & sleeves are also available to suit (compatible with Klinger AB12 spares). This unit is a testament of many years of design and uses a tail nut on the drain and top cap so left and right versions can be achieved with the same unit.

| Working Pressure | 0 to 17 Bar |

|---|---|

| Static Test Pressure | 34 Bar |

| Temperature Range | 0°C to 225°C |

| Made To | AS 1271-2003 |

| Body | Bronze |

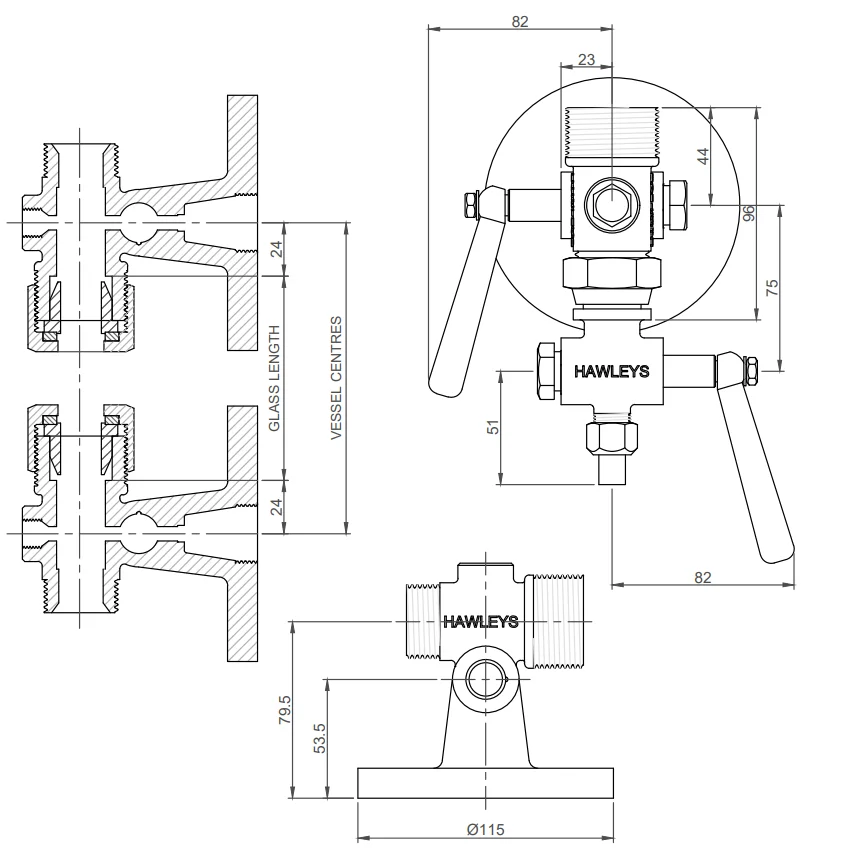

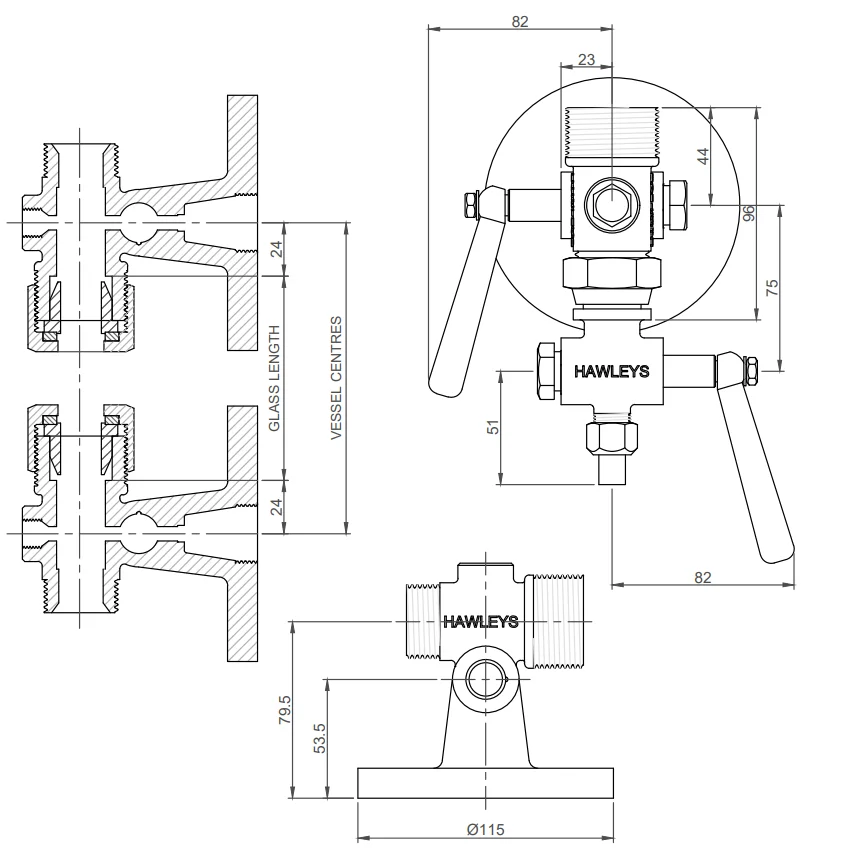

All Dimensions in mm unless stated otherwise

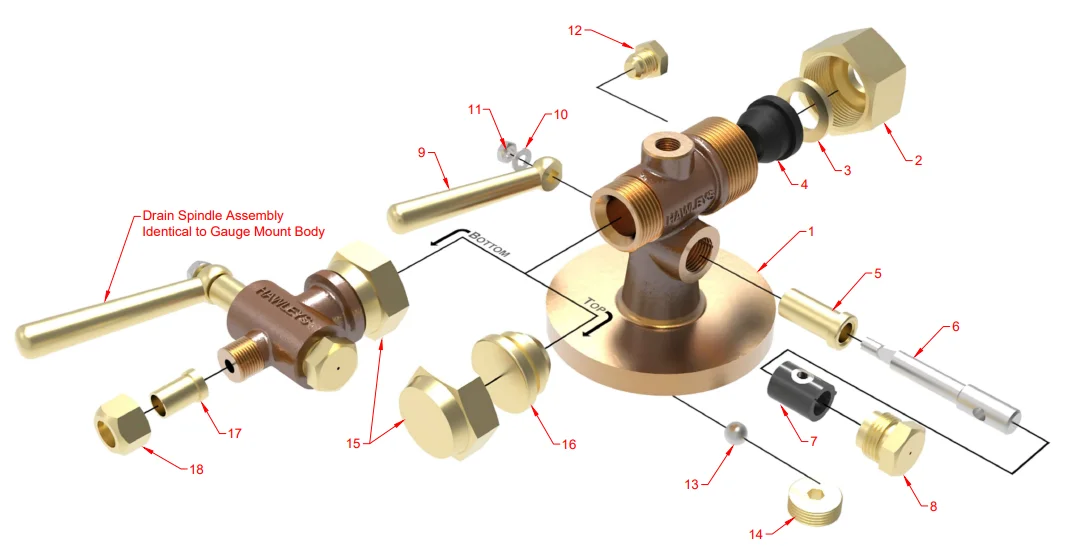

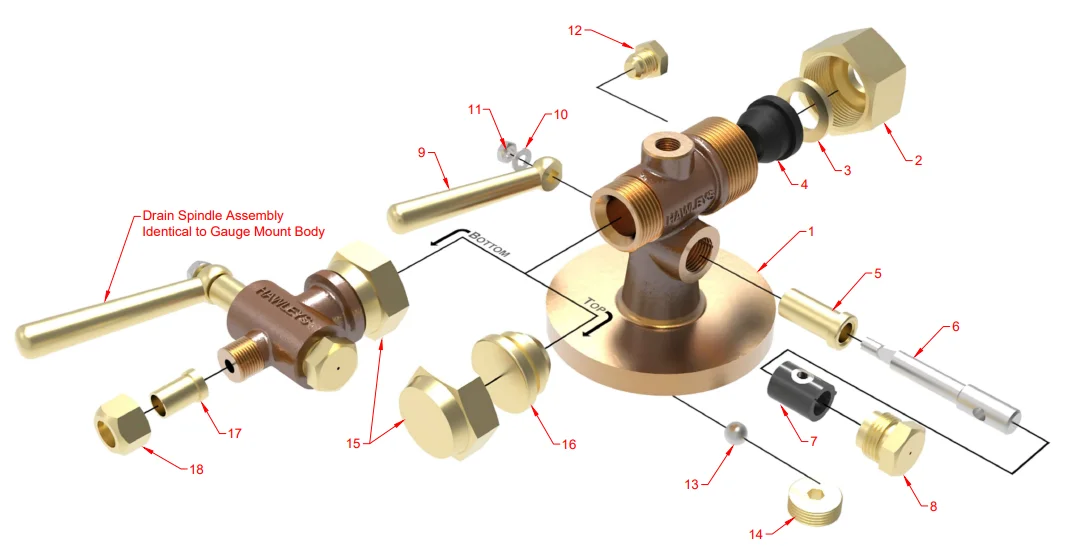

| Item | Description | Material |

|---|---|---|

| 1 | Mount Body | Bronze |

| 2 | Glass Tightening Nut | Brass |

| 3 | Gland Ring | Brass |

| 4 | Gauge Cone | EPDM |

| 5 | Neck Bush | Brass |

| 6 | AB12 Spindle | 316SS |

| 7 | AB12 Graphite Sleeve | Graphite |

| 8 | Sleeve Plug | Brass |

| 9 | Handle | Brass |

| 10 | Spindle Washer | 304 SS |

| 11 | Spindle Nut | 304 SS |

| 12 | Cleaning Plug | Brass |

| 13 | Safety Ball | 316 SS |

| 14 | Check Plug | Brass |

| 15 | Crimp Nut & Blanking Nut | Brass |

| 16 | Blanking Plug | Brass |

| 17 | Tail Pipe | Brass |

| 18 | Tail Pipe Nut | Brass |

Size 20mm Flanged

Mount Top and Bottom

Orientation The one unit can be easily changed to left or right

Body Bronze

Pressure 17 BAR

Temperature 0°C to 225°C

What is a Boiler Gauge Mount?

A boiler gauge mount is a device that is on the side of a boiler to help check the water level that is inside. It features a top and bottom mount that a borosilicate glass tube will usually sit between showing the water vs steam level. They can be made of various materials and are very common in Bronze such as this mount.

How does a Bronze Boiler Gauge Mount work?

In its simplest form a boiler gauge mount shows the level of water inside a boiler. There are usually two sets on each boiler so if one becomes clogged there is another for redundancy. Both the top and bottom mount have an isolating valve which can be closed off and the drain opened on the bottom mount. This will drain the water and steam in the glass tube and then the process can be reversed to fill the level again. Both mounts have a safety ball which is designed to block off 95% of the flow if the glass breaks.

How do I install a Boiler Gauge Mount?

The gauge mounts will be mounted on the flanges on the side of the boiler. A gasket should be used between both flanges to allow for a bubble tight seal. This is usually done using tanged graphite but other materials can be used as well. Be careful not to overtorque the bolts holding the mounts especially if the boiler flange has a raised face connection as it will try and bend the bronze around this (bronze is a softer material). Once the mounts are installed a borosilicate glass tube can be connected between the two. This is done by removing the gland nut, bronze washer and rubber cone and putting these in order on a precut length of borosilicate gauge glass. Both ends can be inserted into the mounts and then tighten the gland nuts. It is best to pre-mark the glass to get the correct depth in the boiler gauge mounts.

How long will my Boiler Gauge Mount Last?

This will depend upon the media and environment the gauge mount is in but it will last a very long time if cared for. Obviously the gauge cones, packings and spindles are the wear parts and are usually checked or changed at quarterly services.

What are typical uses of Bronze Boiler Gauge Mount?

These are mainly used on boilers however we have seen them used as ordinary water level gauges as well. There are many use cases as long as it is within temperature and pressure limitations with a compatible media.

What makes these Boiler Gauge Mounts so Good?

These mounts took over 3 years of development in conjunction with boiler manufacturers and service technicians. Firstly they are die cast instead of sand cast like most other mounts. This makes them stronger and with less porosity due to the nature of the casting method. Our mounts also feature a tail connection which allows the mounts to be easily changed to right or left hand versions (and the drain to be in any position). The tube cleaning plugs also feature a metal to metal seat which eliminates the need for a copper washer. The glass can be completely passed through our mounts if the drain and covering plug are removed which makes it great for servicing in tight spaces. The washer between the gland nut and rubber cone has a centering recess which stops the washer being in contact with the glass by accident. Our gland nuts also have a longer thread to allow an easier lead in for operators where they don't have to force the rubber cone down to get the thread started.We found this was a common glass failure in other models. All in all it is the best gauge mount we could design and make.

Are AB12 Parts Interchangable?

Absolutely. Standard AB12 parts are interchangeable which include the rubber cones, spindles, graphite packing and neck bush. This makes it easy to service with existing parts.

How long will my product take to get to me?

As we sell these around the world this really depends on where you are. Within Australia it will be within a few days, internationally it will vary depending on location.

What warranty do I get?

All come with a 12 month warranty on the body, threads etc however as the gauge cones, packings and spindles are a perishable part and are changed out at varying service intervals these parts are not covered. We currently have these operating without any problems for many years straight and in reality it will only be the cones, packings (and occasionally spindles) that need changing.

Size 20mm Flanged

Mount Top and Bottom

Orientation The one unit can be easily changed to left or right

Body Bronze

Pressure 17 BAR

Temperature 0°C to 225°C

Flanged Bronze Water Level Gauge mount set which includes a Top and Bottom mount. Used on boilers as a sight level gauge. Made to AS 1271-2003 section 5 and includes self closing isolation ball in the event of rupture of glass (this will not do a full shut off as otherwise you would not be able to blow down the gauge glass, it is made as per the standards specifications for seat engagement). Standard with Graphite packing sleeves and stainless steel spindles. Compatible to AB12 Klinger and to suit 3/4" outside diameter glass (or smaller glass with different rubber cones). This set does not include the glass which needs to be ordered seperately and cut to required length. Utilising a graphite sleeve for the packing ensures a quick and easy renewal of the sleeve. Replacement spindles & sleeves are also available to suit (compatible with Klinger AB12 spares). This unit is a testament of many years of design and uses a tail nut on the drain and top cap so left and right versions can be achieved with the same unit.

| Working Pressure | 0 to 17 Bar |

|---|---|

| Static Test Pressure | 34 Bar |

| Temperature Range | 0°C to 225°C |

| Made To | AS 1271-2003 |

| Body | Bronze |

All Dimensions in mm unless stated otherwise

| Item | Description | Material |

|---|---|---|

| 1 | Mount Body | Bronze |

| 2 | Glass Tightening Nut | Brass |

| 3 | Gland Ring | Brass |

| 4 | Gauge Cone | EPDM |

| 5 | Neck Bush | Brass |

| 6 | AB12 Spindle | 316SS |

| 7 | AB12 Graphite Sleeve | Graphite |

| 8 | Sleeve Plug | Brass |

| 9 | Handle | Brass |

| 10 | Spindle Washer | 304 SS |

| 11 | Spindle Nut | 304 SS |

| 12 | Cleaning Plug | Brass |

| 13 | Safety Ball | 316 SS |

| 14 | Check Plug | Brass |

| 15 | Crimp Nut & Blanking Nut | Brass |

| 16 | Blanking Plug | Brass |

| 17 | Tail Pipe | Brass |

| 18 | Tail Pipe Nut | Brass |