Features:

Size 15mm - 300mm

Temperature Limit 550°C

Max Pressure 200 Bar

Application Industrial Services, Steam, High Temperature Applications

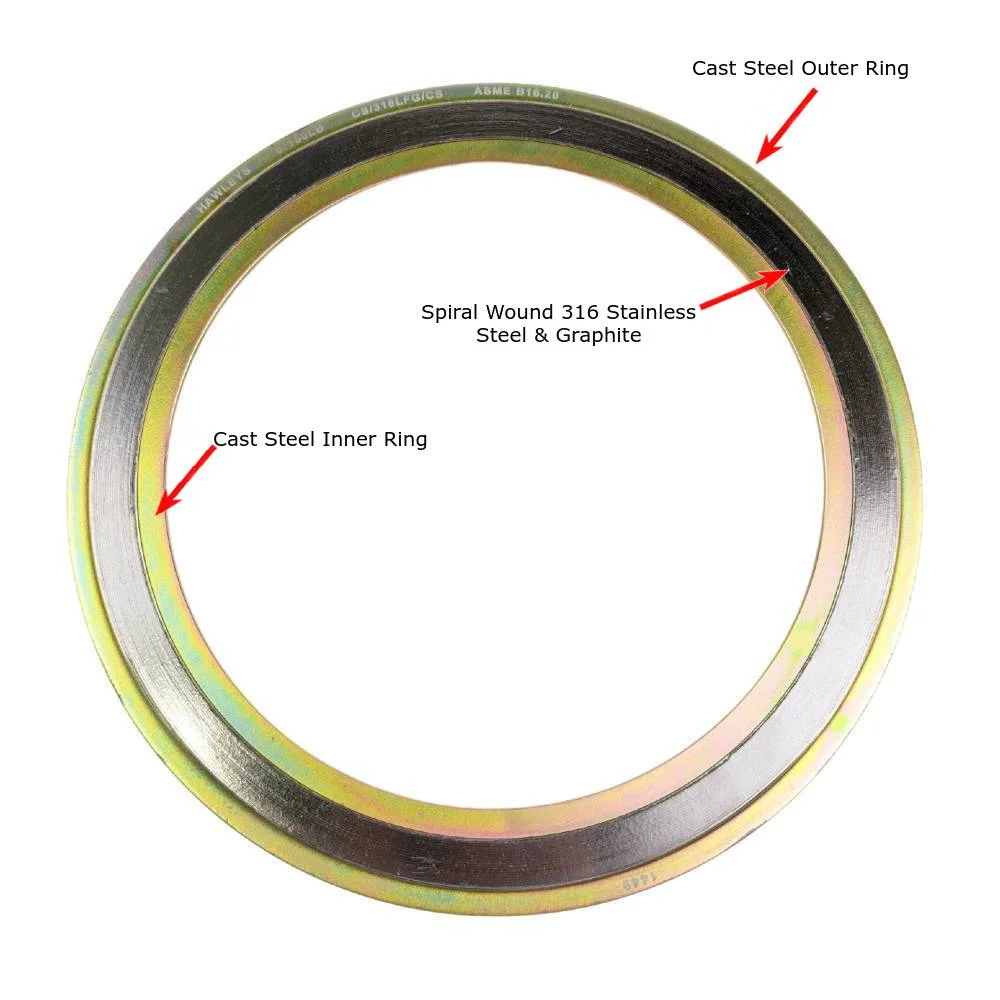

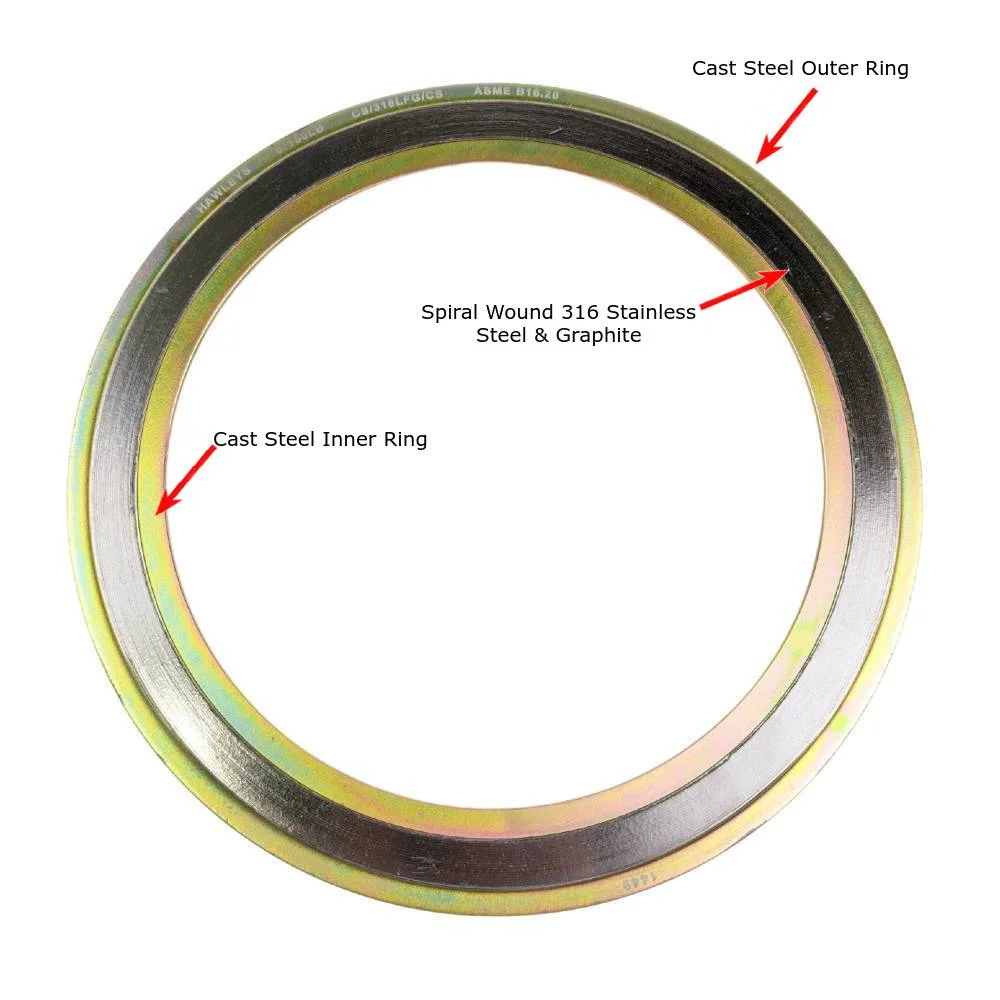

Spiral wound gaskets are made using 316L Stainless Steel windings and graphite filler for the body of the gasket. They have a carbon steel outer and inner ring. The inner ring guards against unwinding of the gasket and gives a smooth flow of product past the flange assembly. These Spiral Wound Gaskets are manufactured to API601.

Size 15mm - 300mm

Temperature Limit 550°C

Max Pressure 200 Bar

Application Industrial Services, Steam, High Temperature Applications

What is a Spiral Wound Gasket?

Spiral Wound Gaskets are a combination of hard and soft materials that are wound together to form a sealing ring. In this case the middle sealing layer is composed of 316 Stainless Steel and Graphite wound together in a spiral then contained by an outer and inner ring both made of cast steel.

How does a Spiral Wound Gasket work?

A Spiral Wound Gasket forms a sealing layer between two surfaces (usually two flange faces). The middle ring (in these spiral wounds as they have an inner and outer ring, some only have an outer ring) provides the sealing surface as it is the softer material been made up of 316 Stainless Steel and Graphite wound together. The inner and outer ring are there to contain the sealing ring and help locate the gasket.

How long will my Spiral Wound Gasket last?

Spiral Wound Gaskets can be very durable as long as they are installed correctly. Most problems are encountered when the spiral wound is taken out where it may run the risk of unwinding. The extra inner ring will help prevent this from happening but it should still be carefully removed as it may bind on the mating surfaces. In practice a lot of spiral wounds are replaced every time the pipework is taken apart.

What are typical uses of a Spiral Wound Gasket?

Spiral Wound Gaskets are mostly used in high temperature applications where other soft cut gaskets may not be as desirable. This is very common in steam lines as the gasket can withstand high operating temperatures and is quite inert to the media.

How do I install a Spiral Wound Gasket?

The two mating surfaces which the Spiral Wound Gasket will form the seal between need to be thoroughly cleaned to make sure there is no dirt or debris on the faces. Once this is achieved and the surfaces look even (if the surface is too worn a spiral wound gasket will struggle to form a seal) the two ends can be bought together with the spiral wound forming the middle seal. Care must be taken to ensure the spiral wound is concentric in the pipe so it is not in the flow path and is mating on the sealing surfaces only. Once this is achieved the pipe/flange bolts can be tightened in a diagonal direction to ensure an even sealing pressure is achieved.

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days.

What warranty do I get?

All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all Spiral Wound Gaskets are inspected so there are rarely any issues. Also once your valve is in and operating it will most likely continue to do so for a very long time.

Size 15mm - 300mm

Temperature Limit 550°C

Max Pressure 200 Bar

Application Industrial Services, Steam, High Temperature Applications

Spiral wound gaskets are made using 316L Stainless Steel windings and graphite filler for the body of the gasket. They have a carbon steel outer and inner ring. The inner ring guards against unwinding of the gasket and gives a smooth flow of product past the flange assembly. These Spiral Wound Gaskets are manufactured to API601.