Features:

Size 1/4" BSP only

Function 3 way normally Closed (power to open)

Valve Operation Direct Acting

Body 304 Stainless Steel

Seat FKM

Pressure Range 0 to 13 BAR (depend on size)

Media Petrochemical, Air, Fluid

A three way normally closed (power to open) direct acting solenoid valve with a 304 Stainless Steel machined body and stainless steel operator. Suitable for low head and zero head applications with a Viton (FKM) seat. Liquids to 50 centistoke viscosity. Standard coil is weatherproof to IP65 and has LED illuminated plug. Typical Applications include pilot valve, tank drain, iodine dosing for dairies, chemicals and other general industry. Threads conform to ISO7.1 sealing threads. Please note the exhaust port on the top of the operator is 1/8" BSP.

*Voltages available; 12vDC, 24vDC, 24vAC, 110vAC, 240vAC, 415vAC

Please note that the exhaust port in both models is 1/8" BSP male thread on the operator.

For Installation and Maintenance instructions please click here or find in our References section under Valve Installation and Maintenance for Solenoid Valves.

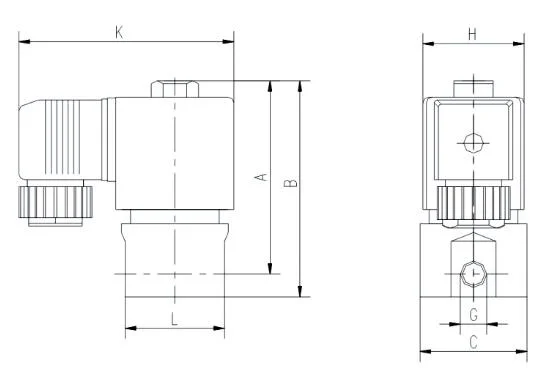

All dimensions in mm unless shown otherwise.

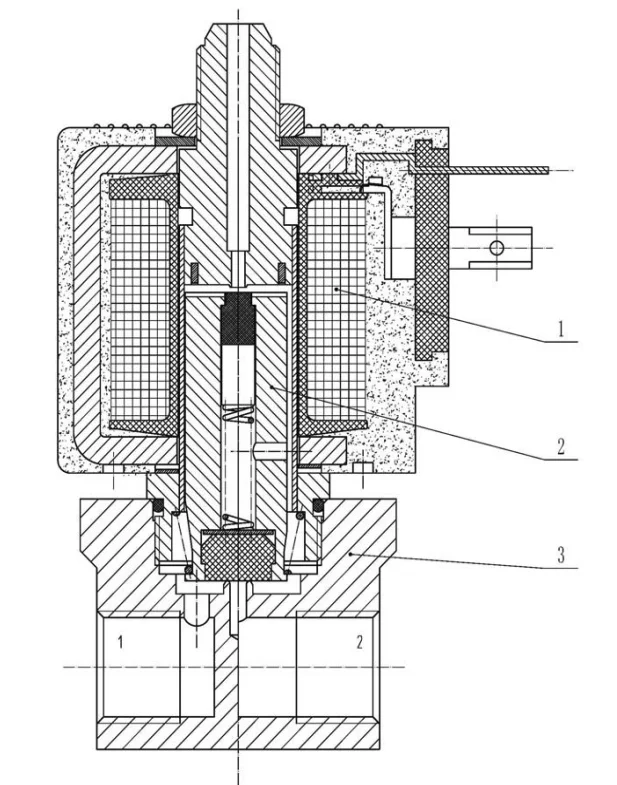

| Number | Item | Material |

|---|---|---|

| 1 | Coil | Epoxy |

| 2 | Armature | Martensitic stainless steel |

| 3 | Valve Body | 304 Stainless Steel |

Size 1/4" BSP only

Function 3 way normally Closed (power to open)

Valve Operation Direct Acting

Body 304 Stainless Steel

Seat FKM

Pressure Range 0 to 13 BAR (depend on size)

Media Petrochemical, Air, Fluid

What is a Stainless Steel 3 Way Direct Acting Normally Closed Solenoid Valve, and what are its primary applications in various industries?

How does a 3-way solenoid valve operate, and what are its advantages in fluid control systems?

Why is stainless steel chosen as the material for this type of solenoid valve, and what are the benefits of using stainless steel in fluid handling systems?

What are the typical applications where a Stainless Steel 3 Way Direct Acting Normally Closed Solenoid Valve is commonly used?

Are there any specific considerations for installation, maintenance, or safety when using Stainless Steel 3 Way Direct Acting Normally Closed Solenoid Valves in fluid handling systems?

Size 1/4" BSP only

Function 3 way normally Closed (power to open)

Valve Operation Direct Acting

Body 304 Stainless Steel

Seat FKM

Pressure Range 0 to 13 BAR (depend on size)

Media Petrochemical, Air, Fluid

A three way normally closed (power to open) direct acting solenoid valve with a 304 Stainless Steel machined body and stainless steel operator. Suitable for low head and zero head applications with a Viton (FKM) seat. Liquids to 50 centistoke viscosity. Standard coil is weatherproof to IP65 and has LED illuminated plug. Typical Applications include pilot valve, tank drain, iodine dosing for dairies, chemicals and other general industry. Threads conform to ISO7.1 sealing threads. Please note the exhaust port on the top of the operator is 1/8" BSP.

*Voltages available; 12vDC, 24vDC, 24vAC, 110vAC, 240vAC, 415vAC

Please note that the exhaust port in both models is 1/8" BSP male thread on the operator.

For Installation and Maintenance instructions please click here or find in our References section under Valve Installation and Maintenance for Solenoid Valves.

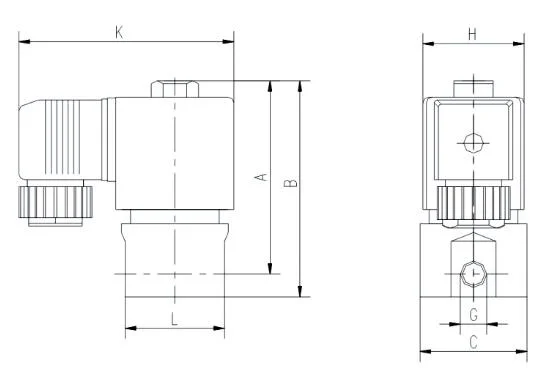

All dimensions in mm unless shown otherwise.

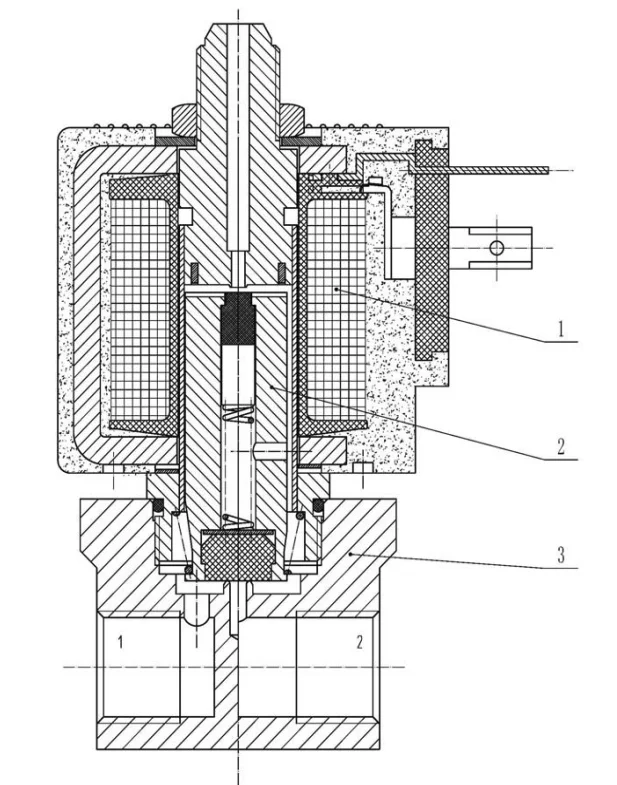

| Number | Item | Material |

|---|---|---|

| 1 | Coil | Epoxy |

| 2 | Armature | Martensitic stainless steel |

| 3 | Valve Body | 304 Stainless Steel |