Features:

Size 3/8" to 2" BSP

Function Normally Closed (power to open)

Valve Operation Coupled Diaphragm

Body 316 Stainless Steel

Seat FKM

Pressure Range 0 to 10 BAR

Media Petrochemical

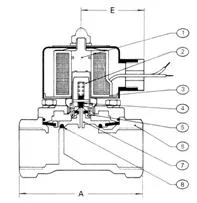

A high flow valve with a 316 Stainless Steel forged body and stainless steel operator. Suitable for low head and zero head applications. Available in various seat materials including Viton (standard), Silicone, Neoprene, EPDM & Nitrile (contact us for any seals other than standard). Liquids to 40cst viscosity. Standard coil is weatherproof to IP65 and has LED illuminated plug. Typical Applications include: Petrochemical, diesel farms, vacuum packaging, tank drain or low pressure service & general industry. Threads conform to ISO 7.1 Sealing Threads.

*Voltages available; 12vDC, 24vDC, 24vAC, 110vAC, 240vAC, 415vAC

For Installation and Maintenance instructions please click here or find in our References section under Valve Installation and Maintenance for Solenoid Valves.

.webp)

All dimensions in mm.

Size 3/8" to 2" BSP

Function Normally Closed (power to open)

Valve Operation Coupled Diaphragm

Body 316 Stainless Steel

Seat FKM

Pressure Range 0 to 10 BAR

Media Petrochemical

What is a Stainless Steel Petrochemical Normally Closed Zero Differential Solenoid Valve, and what are its primary applications in petrochemical industries?

Why is stainless steel commonly chosen as the material for this type of solenoid valve in petrochemical applications?

What are the key features and benefits of using Stainless Steel Petrochemical Normally Closed Zero Differential Solenoid Valves in petrochemical processes?

How does a normally closed zero differential solenoid valve operate, and what is its role in controlling fluid flow in petrochemical systems?

What distinguishes a normally closed zero differential solenoid valve from other types of solenoid valves, and why might it be preferred in certain petrochemical applications?

Size 3/8" to 2" BSP

Function Normally Closed (power to open)

Valve Operation Coupled Diaphragm

Body 316 Stainless Steel

Seat FKM

Pressure Range 0 to 10 BAR

Media Petrochemical

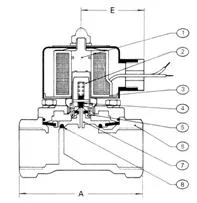

A high flow valve with a 316 Stainless Steel forged body and stainless steel operator. Suitable for low head and zero head applications. Available in various seat materials including Viton (standard), Silicone, Neoprene, EPDM & Nitrile (contact us for any seals other than standard). Liquids to 40cst viscosity. Standard coil is weatherproof to IP65 and has LED illuminated plug. Typical Applications include: Petrochemical, diesel farms, vacuum packaging, tank drain or low pressure service & general industry. Threads conform to ISO 7.1 Sealing Threads.

*Voltages available; 12vDC, 24vDC, 24vAC, 110vAC, 240vAC, 415vAC

For Installation and Maintenance instructions please click here or find in our References section under Valve Installation and Maintenance for Solenoid Valves.

.webp)

All dimensions in mm.