Features:

Size 3 to 9

Temperature 243°C

Body Galvanized Carbon Steel

Pressure Range 0 to 35 BAR

Application Water and Steam

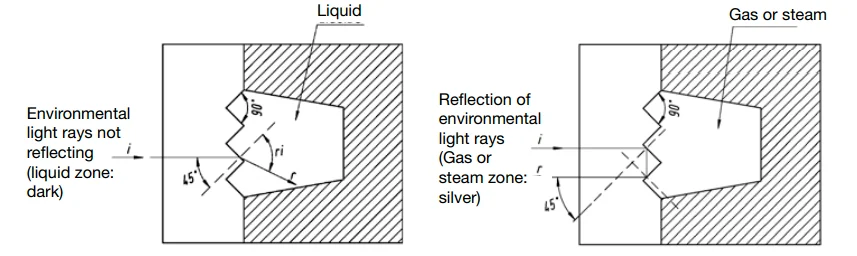

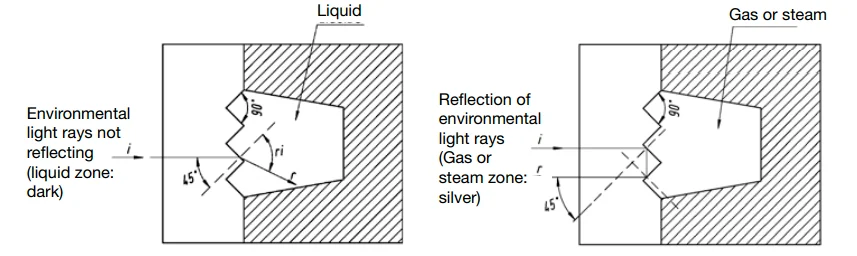

Reflex Liquid Level Gauges distinguish the liquid and steam level using the principles of refraction. The reflex glass used in the gauge features "V" shaped grooves which when in contact with the liquid or steam (air or gas) either reflect the visible light or absorb it. The light that enters through the glass is absorbed by the liquid and reflected by the steam (air or gas), which is due to the difference in refractive index of the two medias. The liquid filled portion of the glass will appear black, whilst the space occupied by the steam (air or gas) will appear a silvery-white colour.

To size the appropriate Reflex Liquid Level Gauge for the specific application, refer to the Dimensions tab which illustrates the different size models that are available to suit type A glass.

Reflex level gauges can be used in a wide range of applications and offer great advantages to due their low inital and operating costs. Their are certain applications where this style of gauge is not suitable such as:

For these applications it is recommended to use a Transparent Level Gauge and in the case of the corrosive or solvent media a combination of a Transparent Level Gauge and a Mica Sheild to protect the glass.

The following diagrams illustrate the refractive principles upon which these Reflex Level Gauges operate.

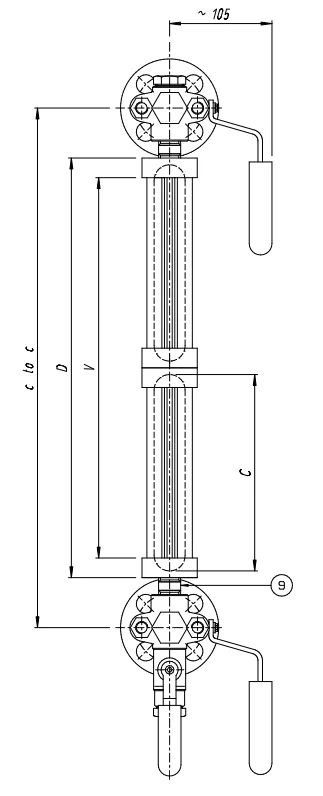

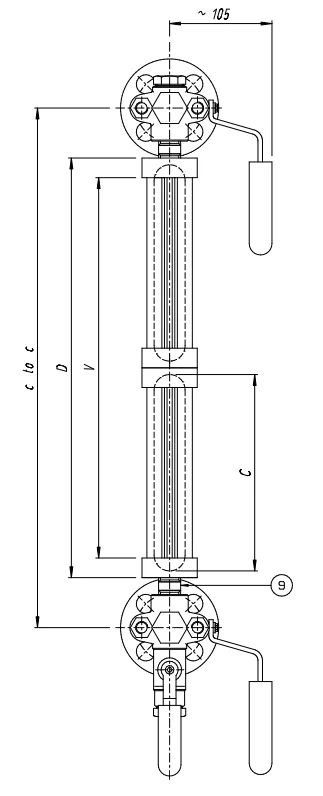

| Size | C to C min. | D | V | C |

|---|---|---|---|---|

| 3 | 285 | 178 | 141 | 165 |

| 4 | 310 | 203 | 166 | 190 |

| 5 | 340 | 233 | 196 | 220 |

| 6 | 370 | 263 | 226 | 250 |

| 7 | 400 | 293 | 256 | 280 |

| 8 | 440 | 333 | 296 | 320 |

| 9 | 460 | 353 | 313 | 340 |

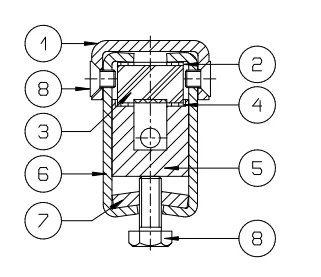

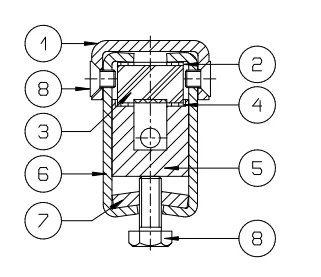

| Number | Description |

|---|---|

| 1 | Safety Clamps |

| 2 | Upper Gasket |

| 3 | Reflex Glass |

| 4 | Lower Gasket |

| 5 | Body |

| 6 | Cover Plate |

| 7 | Tightening Plate |

| 8 | Screw |

| 9 | Nipple |

Size 3 to 9

Temperature 243°C

Body Galvanized Carbon Steel

Pressure Range 0 to 35 BAR

Application Water and Steam

Size 3 to 9

Temperature 243°C

Body Galvanized Carbon Steel

Pressure Range 0 to 35 BAR

Application Water and Steam

Reflex Liquid Level Gauges distinguish the liquid and steam level using the principles of refraction. The reflex glass used in the gauge features "V" shaped grooves which when in contact with the liquid or steam (air or gas) either reflect the visible light or absorb it. The light that enters through the glass is absorbed by the liquid and reflected by the steam (air or gas), which is due to the difference in refractive index of the two medias. The liquid filled portion of the glass will appear black, whilst the space occupied by the steam (air or gas) will appear a silvery-white colour.

To size the appropriate Reflex Liquid Level Gauge for the specific application, refer to the Dimensions tab which illustrates the different size models that are available to suit type A glass.

Reflex level gauges can be used in a wide range of applications and offer great advantages to due their low inital and operating costs. Their are certain applications where this style of gauge is not suitable such as:

For these applications it is recommended to use a Transparent Level Gauge and in the case of the corrosive or solvent media a combination of a Transparent Level Gauge and a Mica Sheild to protect the glass.

The following diagrams illustrate the refractive principles upon which these Reflex Level Gauges operate.

| Size | C to C min. | D | V | C |

|---|---|---|---|---|

| 3 | 285 | 178 | 141 | 165 |

| 4 | 310 | 203 | 166 | 190 |

| 5 | 340 | 233 | 196 | 220 |

| 6 | 370 | 263 | 226 | 250 |

| 7 | 400 | 293 | 256 | 280 |

| 8 | 440 | 333 | 296 | 320 |

| 9 | 460 | 353 | 313 | 340 |

| Number | Description |

|---|---|

| 1 | Safety Clamps |

| 2 | Upper Gasket |

| 3 | Reflex Glass |

| 4 | Lower Gasket |

| 5 | Body |

| 6 | Cover Plate |

| 7 | Tightening Plate |

| 8 | Screw |

| 9 | Nipple |