Features:

Size 1/2" to 2" BSPT

Body Bronze

Application Steam

Inlet Pressure Range 0 to 17 Bar

Outlet Pressure Range 0.2 to 10 BAR

Temperature 0°C to 210°C

GD-30 Pressure Reducing Valves for Steam.

| Application | Steam |

|---|---|

| Type | Direct-Acting |

| Inlet Pressure | 0 to 17 Bar |

| Reduced Pressure | 0.2 to 10 Bar |

| Connection | BSPT (ISO7.1 Rc) |

| Minimum Differential Pressure | 0.5 Bar |

| Maximum Pressure Reduction Ratio | 10:1 |

| Temperature | 0 to 210°C |

| Body | Bronze |

| Valve & Seat | Stainless Steel |

| Bellows | Phosphorous Bronze |

Flow Rate in kg/hr

| P1 (MPa) | P2 (MPa) | 1/2" BSPT | 3/4" BSPT | 1" BSPT |

|---|---|---|---|---|

| 2.00 | 0.97 | 240 | 278 | 464 |

| 0.69 | 240 | 278 | 464 | |

| 0.48 | 217 | 250 | 420 | |

| 0.27 | 140 | 163 | 270 | |

| 1.89 | 0.97 | 240 | 278 | 464 |

| 0.83 | 240 | 278 | 464 | |

| 0.48 | 213 | 246 | 409 | |

| 0.19 | 134 | 156 | 255 | |

| 1.72 | 0.97 | 238 | 275 | 460 |

| 0.83 | 250 | 265 | 471 | |

| 0.48 | 210 | 240 | 405 | |

| 0.17 | 125 | 145 | 240 | |

| 1.55 | 0.97 | 220 | 260 | 430 |

| 0.8 | 225 | 265 | 436 | |

| 0.59 | 210 | 245 | 410 | |

| 0.16 | 115 | 135 | 225 | |

| 1.38 | 0.97 | 209 | 235 | 395 |

| 0.8 | 215 | 245 | 410 | |

| 0.55 | 195 | 225 | 375 | |

| 0.14 | 95 | 110 | 175 | |

| 1.24 | 0.97 | 185 | 220 | 360 |

| 0.8 | 195 | 230 | 390 | |

| 0.48 | 175 | 195 | 335 | |

| 0.12 | 75 | 85 | 140 | |

| 1.03 | 0.83 | 130 | 151 | 250 |

| 0.59 | 165 | 191 | 320 | |

| 0.38 | 135 | 160 | 270 | |

| 0.1 | 60 | 75 | 115 | |

| 0.83 | 0.66 | 105 | 125 | 205 |

| 0.48 | 125 | 141 | 235 | |

| 0.31 | 109 | 121 | 204 | |

| 0.08 | 50 | 55 | 90 | |

| 0.69 | 0.55 | 92 | 110 | 180 |

| 0.45 | 102 | 119 | 198 | |

| 0.28 | 90 | 105 | 170 | |

| 0.07 | 31 | 36 | 60 | |

| 0.55 | 0.44 | 80 | 93 | 155 |

| 0.37 | 85 | 102 | 160 | |

| 0.16 | 55 | 62 | 100 | |

| 0.05 | 27 | 35 | 49 | |

| 0.40 | 0.33 | 62 | 70 | 120 |

| 0.28 | 68 | 75 | 131 | |

| 0.12 | 41 | 47 | 77 | |

| 0.04 | 25 | 33 | 45 | |

| 0.34 | 0.28 | 59 | 65 | 110 |

| 0.14 | 45 | 52 | 85 | |

| 0.03 | 22 | 28 | 40 | |

| 0.28 | 0.22 | 45 | 55 | 85 |

| 0.14 | 36 | 44 | 72 | |

| 0.03 | 18 | 25 | 35 | |

| 0.20 | 0.16 | 28 | 32 | 51 |

| 0.1 | 24 | 27 | 46 | |

| 0.02 | 15 | 18 | 27 | |

| 0.14 | 0.09 | 24 | 28 | 48 |

| 0.05 | 19 | 25 | 35 | |

| 0.10 | 0.05 | 22 | 25 | 42 |

P1 = Inlet Pressure , P2 = Outlet Pressure

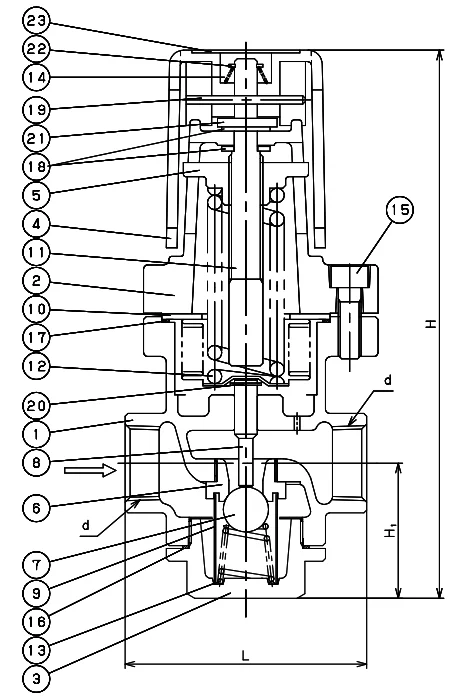

| Size | d | L | H1 | H | Kg |

|---|---|---|---|---|---|

| 15 | 1/2" BSPT | 80 | 47 | 191 | 1.9 |

| 20 | 3/4" BSPT | 85 | 47 | 191 | 1.9 |

| 25 | 1" BSPT | 95 | 47 | 191 | 2 |

All dimensions in mm unless shown otherwise.

| Number | Part | Material | Grade | QTY |

|---|---|---|---|---|

| 1 | Body | Bronze | CAC406 | 1 |

| 2 | Spring Chamber | Aluminium | ADC12 | 1 |

| 3 | Cap | Brass | C3771 | 1 |

| 4 | Handle | Polycarobonate | PC | 1 |

| 5 | Spring Plate | Cast Iron | FC200 | 1 |

| 6 | Valve Seat | Stainless Steel | SUS304 | 1 |

| 7 | Valve | Stainless Steel | SUS440 | 1 |

| 8 | Spindle | Stainless Steel | SUS304 | 1 |

| 9 | Screen | Stainless Steel | SUS304 | 1 |

| 10 | Bellows | Phosphorous Bronze | C5212 | 1 |

| 11 | Adjusting Screw | Carbon Steel | SUM22 | 1 |

| 12 | Spring | Alloy Steel | SWOSC | 1 |

| 13 | Spring | Stainless Steel | SUS304 | 1 |

| 14 | Spring | Stainless Steel | SUS304 | 1 |

| 15 | Bolts | Carbon Steel | SCM435 | 4 |

| 16 | Gasket | Copper | C1100 | 1 |

| 17 | Gasket | Copper | C1100 | 1 |

| 18 | Washer | Stainless Steel | SUS304 | 2 |

| 19 | Pin | Stainless Steel | SUS304 | 1 |

| 20 | E Rign | Stainless Steel | SUS304 | 1 |

| 21 | Split Pin | Stainless Steel | SUS304 | 1 |

| 22 | Push Nut | Stainless Steel | SUS304 | 1 |

| 23 | Name Plate | Aluminium | A1050P | 1 |

Size 1/2" to 2" BSPT

Body Bronze

Application Steam

Inlet Pressure Range 0 to 17 Bar

Outlet Pressure Range 0.2 to 10 BAR

Temperature 0°C to 210°C

What is a Bronze Pressure Reducing Valve for Steam, and what is its primary purpose?

How does a pressure reducing valve work in a steam system?

Why is bronze commonly used as the material for these valves?

What are the key components of a bronze pressure reducing valve for steam?

What is the ideal pressure range for steam systems where these valves are used?

Size 1/2" to 2" BSPT

Body Bronze

Application Steam

Inlet Pressure Range 0 to 17 Bar

Outlet Pressure Range 0.2 to 10 BAR

Temperature 0°C to 210°C

GD-30 Pressure Reducing Valves for Steam.

| Application | Steam |

|---|---|

| Type | Direct-Acting |

| Inlet Pressure | 0 to 17 Bar |

| Reduced Pressure | 0.2 to 10 Bar |

| Connection | BSPT (ISO7.1 Rc) |

| Minimum Differential Pressure | 0.5 Bar |

| Maximum Pressure Reduction Ratio | 10:1 |

| Temperature | 0 to 210°C |

| Body | Bronze |

| Valve & Seat | Stainless Steel |

| Bellows | Phosphorous Bronze |

Flow Rate in kg/hr

| P1 (MPa) | P2 (MPa) | 1/2" BSPT | 3/4" BSPT | 1" BSPT |

|---|---|---|---|---|

| 2.00 | 0.97 | 240 | 278 | 464 |

| 0.69 | 240 | 278 | 464 | |

| 0.48 | 217 | 250 | 420 | |

| 0.27 | 140 | 163 | 270 | |

| 1.89 | 0.97 | 240 | 278 | 464 |

| 0.83 | 240 | 278 | 464 | |

| 0.48 | 213 | 246 | 409 | |

| 0.19 | 134 | 156 | 255 | |

| 1.72 | 0.97 | 238 | 275 | 460 |

| 0.83 | 250 | 265 | 471 | |

| 0.48 | 210 | 240 | 405 | |

| 0.17 | 125 | 145 | 240 | |

| 1.55 | 0.97 | 220 | 260 | 430 |

| 0.8 | 225 | 265 | 436 | |

| 0.59 | 210 | 245 | 410 | |

| 0.16 | 115 | 135 | 225 | |

| 1.38 | 0.97 | 209 | 235 | 395 |

| 0.8 | 215 | 245 | 410 | |

| 0.55 | 195 | 225 | 375 | |

| 0.14 | 95 | 110 | 175 | |

| 1.24 | 0.97 | 185 | 220 | 360 |

| 0.8 | 195 | 230 | 390 | |

| 0.48 | 175 | 195 | 335 | |

| 0.12 | 75 | 85 | 140 | |

| 1.03 | 0.83 | 130 | 151 | 250 |

| 0.59 | 165 | 191 | 320 | |

| 0.38 | 135 | 160 | 270 | |

| 0.1 | 60 | 75 | 115 | |

| 0.83 | 0.66 | 105 | 125 | 205 |

| 0.48 | 125 | 141 | 235 | |

| 0.31 | 109 | 121 | 204 | |

| 0.08 | 50 | 55 | 90 | |

| 0.69 | 0.55 | 92 | 110 | 180 |

| 0.45 | 102 | 119 | 198 | |

| 0.28 | 90 | 105 | 170 | |

| 0.07 | 31 | 36 | 60 | |

| 0.55 | 0.44 | 80 | 93 | 155 |

| 0.37 | 85 | 102 | 160 | |

| 0.16 | 55 | 62 | 100 | |

| 0.05 | 27 | 35 | 49 | |

| 0.40 | 0.33 | 62 | 70 | 120 |

| 0.28 | 68 | 75 | 131 | |

| 0.12 | 41 | 47 | 77 | |

| 0.04 | 25 | 33 | 45 | |

| 0.34 | 0.28 | 59 | 65 | 110 |

| 0.14 | 45 | 52 | 85 | |

| 0.03 | 22 | 28 | 40 | |

| 0.28 | 0.22 | 45 | 55 | 85 |

| 0.14 | 36 | 44 | 72 | |

| 0.03 | 18 | 25 | 35 | |

| 0.20 | 0.16 | 28 | 32 | 51 |

| 0.1 | 24 | 27 | 46 | |

| 0.02 | 15 | 18 | 27 | |

| 0.14 | 0.09 | 24 | 28 | 48 |

| 0.05 | 19 | 25 | 35 | |

| 0.10 | 0.05 | 22 | 25 | 42 |

P1 = Inlet Pressure , P2 = Outlet Pressure

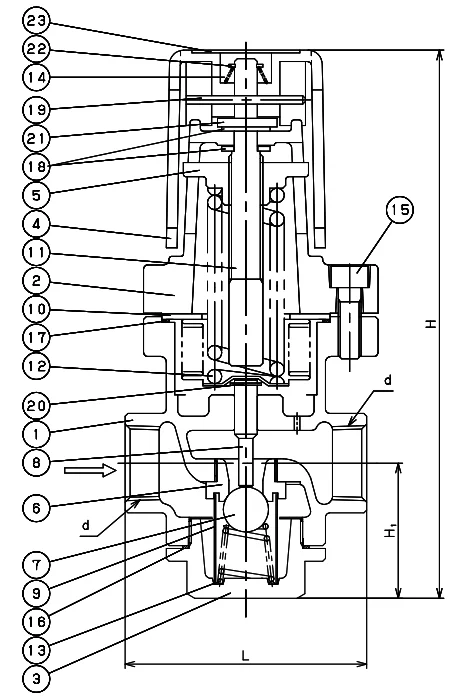

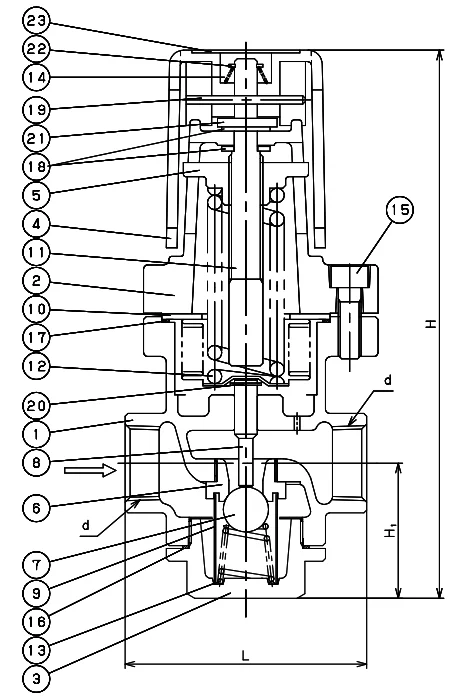

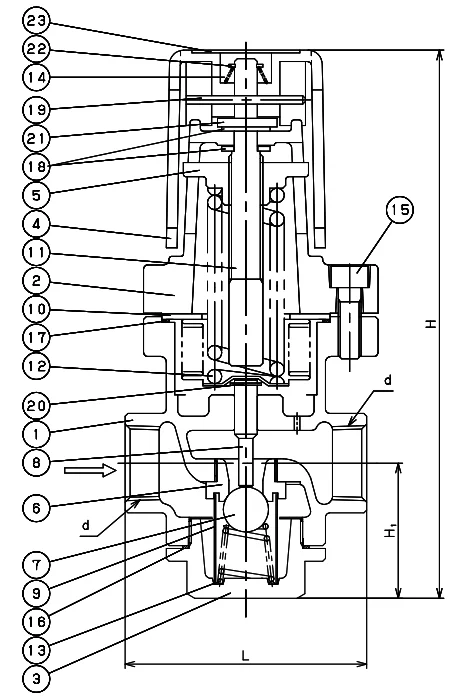

| Size | d | L | H1 | H | Kg |

|---|---|---|---|---|---|

| 15 | 1/2" BSPT | 80 | 47 | 191 | 1.9 |

| 20 | 3/4" BSPT | 85 | 47 | 191 | 1.9 |

| 25 | 1" BSPT | 95 | 47 | 191 | 2 |

All dimensions in mm unless shown otherwise.

| Number | Part | Material | Grade | QTY |

|---|---|---|---|---|

| 1 | Body | Bronze | CAC406 | 1 |

| 2 | Spring Chamber | Aluminium | ADC12 | 1 |

| 3 | Cap | Brass | C3771 | 1 |

| 4 | Handle | Polycarobonate | PC | 1 |

| 5 | Spring Plate | Cast Iron | FC200 | 1 |

| 6 | Valve Seat | Stainless Steel | SUS304 | 1 |

| 7 | Valve | Stainless Steel | SUS440 | 1 |

| 8 | Spindle | Stainless Steel | SUS304 | 1 |

| 9 | Screen | Stainless Steel | SUS304 | 1 |

| 10 | Bellows | Phosphorous Bronze | C5212 | 1 |

| 11 | Adjusting Screw | Carbon Steel | SUM22 | 1 |

| 12 | Spring | Alloy Steel | SWOSC | 1 |

| 13 | Spring | Stainless Steel | SUS304 | 1 |

| 14 | Spring | Stainless Steel | SUS304 | 1 |

| 15 | Bolts | Carbon Steel | SCM435 | 4 |

| 16 | Gasket | Copper | C1100 | 1 |

| 17 | Gasket | Copper | C1100 | 1 |

| 18 | Washer | Stainless Steel | SUS304 | 2 |

| 19 | Pin | Stainless Steel | SUS304 | 1 |

| 20 | E Rign | Stainless Steel | SUS304 | 1 |

| 21 | Split Pin | Stainless Steel | SUS304 | 1 |

| 22 | Push Nut | Stainless Steel | SUS304 | 1 |

| 23 | Name Plate | Aluminium | A1050P | 1 |