Features:

Size 50mm to 300mm

Body Carbon Steel (WCB)

Seat Metal

Pressure 50 Bar @ ambient

Operation Handwheel rising stem

Rising stem Cast Steel (WCB) ANSI 300 Flanged Gate Valve. Used extensively in petrochemical and high temperature applications as an isolation valve.

| Model | DN | Pressure Range (at Ambient Temp) | Media Temp | Weight (kg) |

|---|---|---|---|---|

| GVWR3-050 | 50 | 0 to 50 Bar | 315°C at 38 Bar | 23 |

| GVWR3-065 | 65 | 0 to 50 Bar | 315°C at 38 Bar | 35 |

| GVWR3-080 | 80 | 0 to 50 Bar | 315°C at 38 Bar | 50 |

| GVWR3-100 | 100 | 0 to 50 Bar | 315°C at 38 Bar | 71 |

| GVWR3-150 | 150 | 0 to 50 Bar | 315°C at 38 Bar | 144 |

| GVWR3-200 | 200 | 0 to 50 Bar | 315°C at 38 Bar | 209 |

| GVWR3-250 | 250 | 0 to 50 Bar | 315°C at 38 Bar | 322 |

| GVWR3-300 | 300 | 0 to 50 Bar | 315°C at 38 Bar | 482 |

| Size | L | D (Flange OD) | D1 (PCD) | D2 (Raised Face OD) | N-ød (Holes) | B (Flange Thickness) | H (Open) | H (Closed) | W (Handwheel Dia.) |

|---|---|---|---|---|---|---|---|---|---|

| 50 | 216 ± 1.5 | 165 | 127 | 92.1 | 8-Ø19 | 20.7 | 408 | 340 | 200 |

| 65 | 241 ± 1.5 | 190 | 149.2 | 104.8 | 8-Ø22.5 | 23.9 | 460 | 386 | 200 |

| 80 | 282 ± 1.5 | 210 | 168.3 | 127 | 8-Ø22.5 | 27 | 530 | 435 | 240 |

| 100 | 305 ± 1.5 | 255 | 200 | 157.2 | 8-Ø22.5 | 30.2 | 619 | 502 | 280 |

| 125 | 381 ± 1.5 | 280 | 235 | 186 | 8-Ø22.5 | 33.4 | 748 | 605 | 320 |

| 150 | 403 ± 1.5 | 320 | 269.9 | 215.9 | 12-Ø22.5 | 35 | 826 | 660 | 360 |

| 200 | 419 ± 1.5 | 380 | 330.2 | 269.9 | 12-Ø25.5 | 39.7 | 1038 | 807 | 400 |

| 250 | 457 ± 1.5 | 445 | 387.4 | 323.8 | 16-Ø28.5 | 46.1 | 1247 | 972 | 450 |

| 300 | 502 ± 2 | 520 | 450.8 | 381 | 16-Ø32 | 49.3 | 1436 | 1107 | 560 |

| 350 | 762 ± 3 | 585 | 514.4 | 412.8 | 20-Ø32 | 52.4 | 1595 | 1230 | 640 |

| 400 | 838 ± 3 | 650 | 571.5 | 469.9 | 20-Ø35 | 55.6 | 1797 | 1383 | 720 |

| 450 | 914 ± 3 | 710 | 628.6 | 533.4 | 24-Ø35 | 58.8 | 1994 | 1530 | 800 |

| 500 | 991 ± 3 | 775 | 685.8 | 584.2 | 24-Ø35 | 62 | 2204 | 1687 | 950 |

| 600 | 1143 ± 3 | 915 | 812.8 | 692.2 | 24-Ø41.5 | 67.3 | 2605 | 1984 | 1100 |

All dimensions in mm unless shown otherwise.

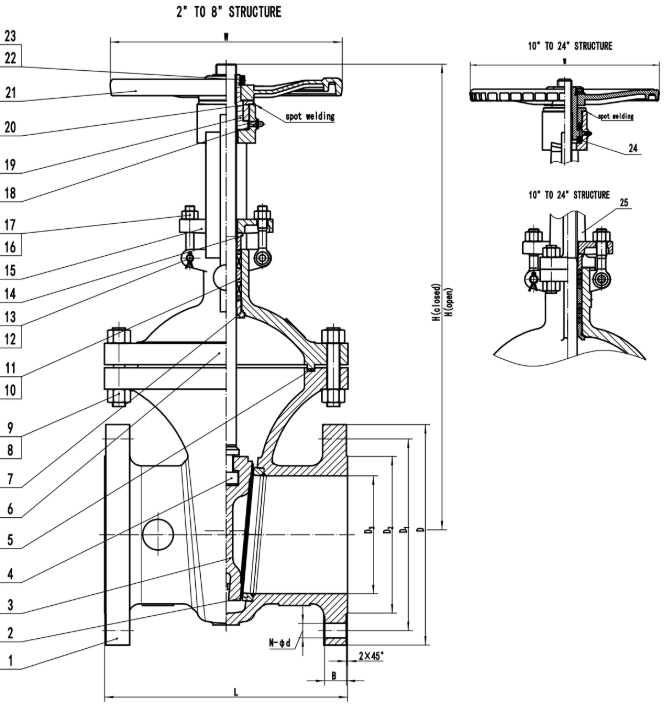

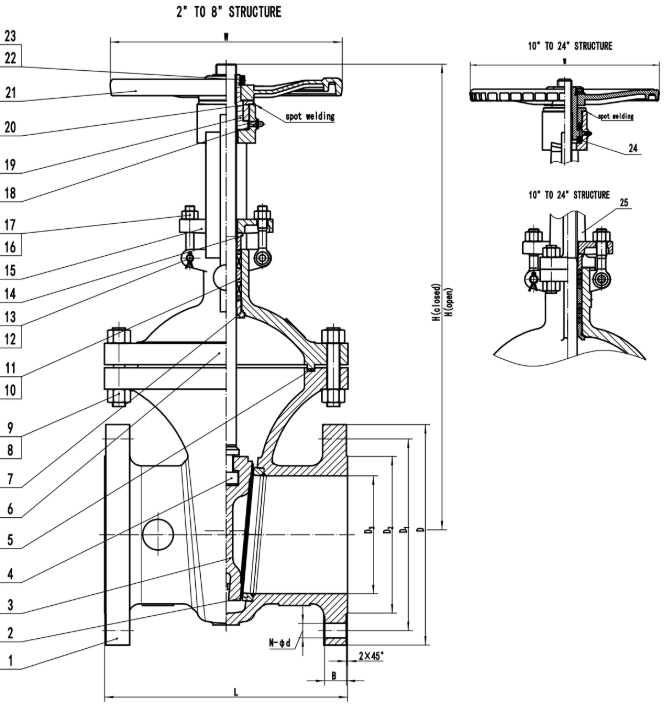

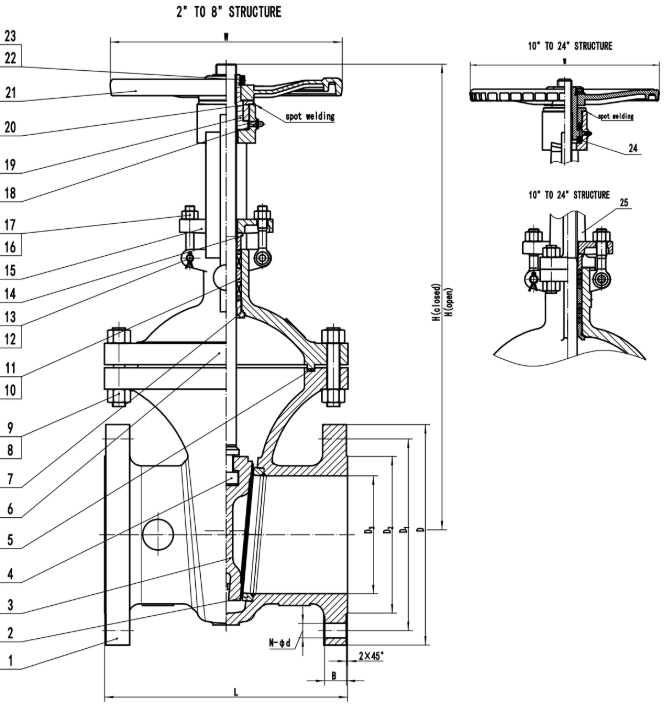

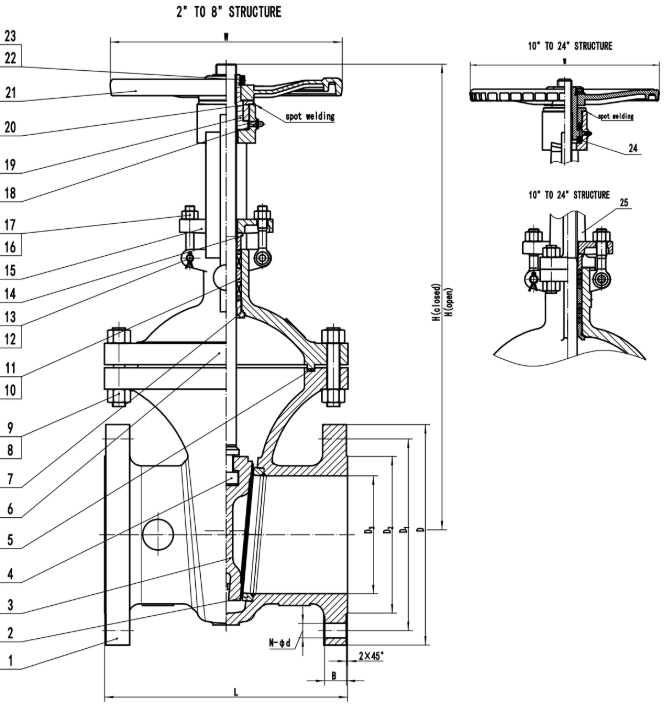

| No. | Part | Material |

|---|---|---|

| 1 | BODY | ASTM A216 WCB |

| 2 | SEAT | ASTM A105+13CR |

| 3 | WEDGE (2"-4") | ASTM A217 CA15+13CR |

| WEDGE (5"-8") | ASTM A216 WCB+13CR | |

| 4 | STEM | ASTM A182 F6a Cl.2 |

| 5 | GASKET | SS304+Graphite |

| 6 | BONNET | ASTM A216 WCB |

| 7 | BACK SEAT | ASTM A276 420 |

| 8 | BOLT | ASTM A193 B7 |

| 9 | NUT | ASTM A194 2H |

| 10 | SPACER RING | ASTM A276 420 |

| 11 | PACKING | Braided Graphite & Die formed Graphite Ring |

| 12 | PIN | AISI 1035 |

| 13 | COTTER | Q235 |

| 14 | GLAND | ASTM A276 420 |

| 15 | GLAND FLANGE | ASTM A216 WCB |

| 16 | EYE BOLT | ASTM A193 B7 |

| 17 | NUT | ASTM A194 2H |

| 18 | GREASE FITTING | C.S |

| 19 | STEM NUT | ASTM A439 D-2 |

| 20 | BEARING GLAND | AISI 1020 |

| 21 | HANDWHEEL | ASTM A536 65-45-12 |

| 22 | LOCK NUT | AISI 1020 |

| 23 | BOLT | AISI 1045 |

| 24 | BEARING | GCr15 |

| 25 | BRACKET | ASTM A216 WCB |

Size 50mm to 300mm

Body Carbon Steel (WCB)

Seat Metal

Pressure 50 Bar @ ambient

Operation Handwheel rising stem

What is an ANSI 300 Flanged Cast Steel Gate Valve, and what is its primary function?

How does a gate valve differ from other types of valves, and where is it typically used?

Why is cast steel commonly used as the material for these valves?

What are the key components of an ANSI 300 Flanged Cast Steel Gate Valve?

What is the ANSI 300 pressure rating, and what does it signify in terms of valve performance?

How do I determine the appropriate size of a gate valve for my specific application?

Are there different types of gate valves available in the ANSI 300 pressure class?

What are the advantages of using a cast steel gate valve over valves made from other materials?

Can a gate valve be used for both on-off and throttling applications?

Are there any limitations or considerations when using gate valves in high-pressure or high-temperature environments?

Size 50mm to 300mm

Body Carbon Steel (WCB)

Seat Metal

Pressure 50 Bar @ ambient

Operation Handwheel rising stem

Rising stem Cast Steel (WCB) ANSI 300 Flanged Gate Valve. Used extensively in petrochemical and high temperature applications as an isolation valve.

| Model | DN | Pressure Range (at Ambient Temp) | Media Temp | Weight (kg) |

|---|---|---|---|---|

| GVWR3-050 | 50 | 0 to 50 Bar | 315°C at 38 Bar | 23 |

| GVWR3-065 | 65 | 0 to 50 Bar | 315°C at 38 Bar | 35 |

| GVWR3-080 | 80 | 0 to 50 Bar | 315°C at 38 Bar | 50 |

| GVWR3-100 | 100 | 0 to 50 Bar | 315°C at 38 Bar | 71 |

| GVWR3-150 | 150 | 0 to 50 Bar | 315°C at 38 Bar | 144 |

| GVWR3-200 | 200 | 0 to 50 Bar | 315°C at 38 Bar | 209 |

| GVWR3-250 | 250 | 0 to 50 Bar | 315°C at 38 Bar | 322 |

| GVWR3-300 | 300 | 0 to 50 Bar | 315°C at 38 Bar | 482 |

| Size | L | D (Flange OD) | D1 (PCD) | D2 (Raised Face OD) | N-ød (Holes) | B (Flange Thickness) | H (Open) | H (Closed) | W (Handwheel Dia.) |

|---|---|---|---|---|---|---|---|---|---|

| 50 | 216 ± 1.5 | 165 | 127 | 92.1 | 8-Ø19 | 20.7 | 408 | 340 | 200 |

| 65 | 241 ± 1.5 | 190 | 149.2 | 104.8 | 8-Ø22.5 | 23.9 | 460 | 386 | 200 |

| 80 | 282 ± 1.5 | 210 | 168.3 | 127 | 8-Ø22.5 | 27 | 530 | 435 | 240 |

| 100 | 305 ± 1.5 | 255 | 200 | 157.2 | 8-Ø22.5 | 30.2 | 619 | 502 | 280 |

| 125 | 381 ± 1.5 | 280 | 235 | 186 | 8-Ø22.5 | 33.4 | 748 | 605 | 320 |

| 150 | 403 ± 1.5 | 320 | 269.9 | 215.9 | 12-Ø22.5 | 35 | 826 | 660 | 360 |

| 200 | 419 ± 1.5 | 380 | 330.2 | 269.9 | 12-Ø25.5 | 39.7 | 1038 | 807 | 400 |

| 250 | 457 ± 1.5 | 445 | 387.4 | 323.8 | 16-Ø28.5 | 46.1 | 1247 | 972 | 450 |

| 300 | 502 ± 2 | 520 | 450.8 | 381 | 16-Ø32 | 49.3 | 1436 | 1107 | 560 |

| 350 | 762 ± 3 | 585 | 514.4 | 412.8 | 20-Ø32 | 52.4 | 1595 | 1230 | 640 |

| 400 | 838 ± 3 | 650 | 571.5 | 469.9 | 20-Ø35 | 55.6 | 1797 | 1383 | 720 |

| 450 | 914 ± 3 | 710 | 628.6 | 533.4 | 24-Ø35 | 58.8 | 1994 | 1530 | 800 |

| 500 | 991 ± 3 | 775 | 685.8 | 584.2 | 24-Ø35 | 62 | 2204 | 1687 | 950 |

| 600 | 1143 ± 3 | 915 | 812.8 | 692.2 | 24-Ø41.5 | 67.3 | 2605 | 1984 | 1100 |

All dimensions in mm unless shown otherwise.

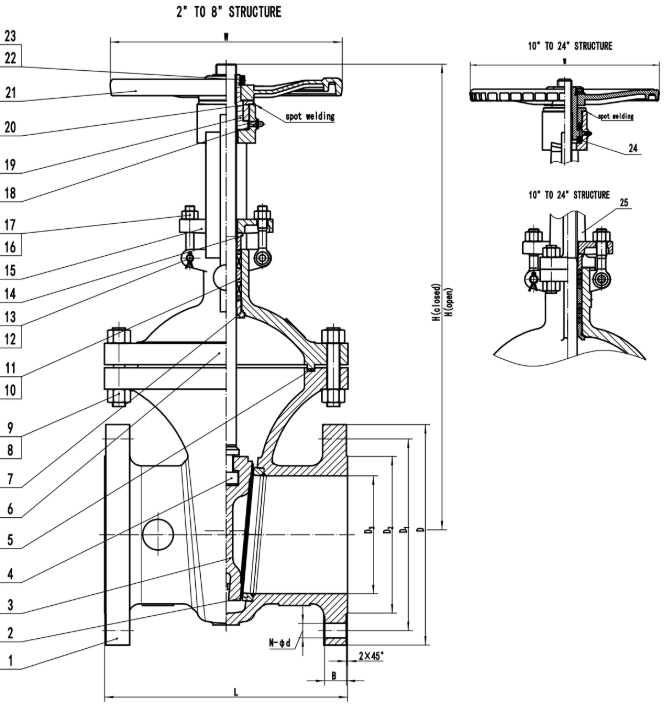

| No. | Part | Material |

|---|---|---|

| 1 | BODY | ASTM A216 WCB |

| 2 | SEAT | ASTM A105+13CR |

| 3 | WEDGE (2"-4") | ASTM A217 CA15+13CR |

| WEDGE (5"-8") | ASTM A216 WCB+13CR | |

| 4 | STEM | ASTM A182 F6a Cl.2 |

| 5 | GASKET | SS304+Graphite |

| 6 | BONNET | ASTM A216 WCB |

| 7 | BACK SEAT | ASTM A276 420 |

| 8 | BOLT | ASTM A193 B7 |

| 9 | NUT | ASTM A194 2H |

| 10 | SPACER RING | ASTM A276 420 |

| 11 | PACKING | Braided Graphite & Die formed Graphite Ring |

| 12 | PIN | AISI 1035 |

| 13 | COTTER | Q235 |

| 14 | GLAND | ASTM A276 420 |

| 15 | GLAND FLANGE | ASTM A216 WCB |

| 16 | EYE BOLT | ASTM A193 B7 |

| 17 | NUT | ASTM A194 2H |

| 18 | GREASE FITTING | C.S |

| 19 | STEM NUT | ASTM A439 D-2 |

| 20 | BEARING GLAND | AISI 1020 |

| 21 | HANDWHEEL | ASTM A536 65-45-12 |

| 22 | LOCK NUT | AISI 1020 |

| 23 | BOLT | AISI 1045 |

| 24 | BEARING | GCr15 |

| 25 | BRACKET | ASTM A216 WCB |

Size 50mm to 300mm

Body Carbon Steel (WCB)

Seat Metal

Pressure 50 Bar @ ambient

Operation Handwheel rising stem

Rising stem Cast Steel (WCB) ANSI 300 Flanged Gate Valve. Used extensively in petrochemical and high temperature applications as an isolation valve.

| Model | DN | Pressure Range (at Ambient Temp) | Media Temp | Weight (kg) |

|---|---|---|---|---|

| GVWR3-050 | 50 | 0 to 50 Bar | 315°C at 38 Bar | 23 |

| GVWR3-065 | 65 | 0 to 50 Bar | 315°C at 38 Bar | 35 |

| GVWR3-080 | 80 | 0 to 50 Bar | 315°C at 38 Bar | 50 |

| GVWR3-100 | 100 | 0 to 50 Bar | 315°C at 38 Bar | 71 |

| GVWR3-150 | 150 | 0 to 50 Bar | 315°C at 38 Bar | 144 |

| GVWR3-200 | 200 | 0 to 50 Bar | 315°C at 38 Bar | 209 |

| GVWR3-250 | 250 | 0 to 50 Bar | 315°C at 38 Bar | 322 |

| GVWR3-300 | 300 | 0 to 50 Bar | 315°C at 38 Bar | 482 |

| Size | L | D (Flange OD) | D1 (PCD) | D2 (Raised Face OD) | N-ød (Holes) | B (Flange Thickness) | H (Open) | H (Closed) | W (Handwheel Dia.) |

|---|---|---|---|---|---|---|---|---|---|

| 50 | 216 ± 1.5 | 165 | 127 | 92.1 | 8-Ø19 | 20.7 | 408 | 340 | 200 |

| 65 | 241 ± 1.5 | 190 | 149.2 | 104.8 | 8-Ø22.5 | 23.9 | 460 | 386 | 200 |

| 80 | 282 ± 1.5 | 210 | 168.3 | 127 | 8-Ø22.5 | 27 | 530 | 435 | 240 |

| 100 | 305 ± 1.5 | 255 | 200 | 157.2 | 8-Ø22.5 | 30.2 | 619 | 502 | 280 |

| 125 | 381 ± 1.5 | 280 | 235 | 186 | 8-Ø22.5 | 33.4 | 748 | 605 | 320 |

| 150 | 403 ± 1.5 | 320 | 269.9 | 215.9 | 12-Ø22.5 | 35 | 826 | 660 | 360 |

| 200 | 419 ± 1.5 | 380 | 330.2 | 269.9 | 12-Ø25.5 | 39.7 | 1038 | 807 | 400 |

| 250 | 457 ± 1.5 | 445 | 387.4 | 323.8 | 16-Ø28.5 | 46.1 | 1247 | 972 | 450 |

| 300 | 502 ± 2 | 520 | 450.8 | 381 | 16-Ø32 | 49.3 | 1436 | 1107 | 560 |

| 350 | 762 ± 3 | 585 | 514.4 | 412.8 | 20-Ø32 | 52.4 | 1595 | 1230 | 640 |

| 400 | 838 ± 3 | 650 | 571.5 | 469.9 | 20-Ø35 | 55.6 | 1797 | 1383 | 720 |

| 450 | 914 ± 3 | 710 | 628.6 | 533.4 | 24-Ø35 | 58.8 | 1994 | 1530 | 800 |

| 500 | 991 ± 3 | 775 | 685.8 | 584.2 | 24-Ø35 | 62 | 2204 | 1687 | 950 |

| 600 | 1143 ± 3 | 915 | 812.8 | 692.2 | 24-Ø41.5 | 67.3 | 2605 | 1984 | 1100 |

All dimensions in mm unless shown otherwise.

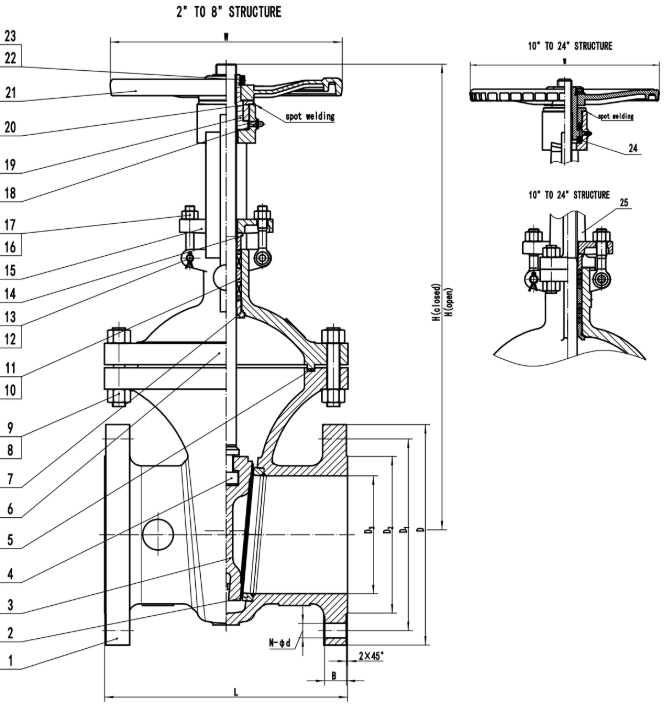

| No. | Part | Material |

|---|---|---|

| 1 | BODY | ASTM A216 WCB |

| 2 | SEAT | ASTM A105+13CR |

| 3 | WEDGE (2"-4") | ASTM A217 CA15+13CR |

| WEDGE (5"-8") | ASTM A216 WCB+13CR | |

| 4 | STEM | ASTM A182 F6a Cl.2 |

| 5 | GASKET | SS304+Graphite |

| 6 | BONNET | ASTM A216 WCB |

| 7 | BACK SEAT | ASTM A276 420 |

| 8 | BOLT | ASTM A193 B7 |

| 9 | NUT | ASTM A194 2H |

| 10 | SPACER RING | ASTM A276 420 |

| 11 | PACKING | Braided Graphite & Die formed Graphite Ring |

| 12 | PIN | AISI 1035 |

| 13 | COTTER | Q235 |

| 14 | GLAND | ASTM A276 420 |

| 15 | GLAND FLANGE | ASTM A216 WCB |

| 16 | EYE BOLT | ASTM A193 B7 |

| 17 | NUT | ASTM A194 2H |

| 18 | GREASE FITTING | C.S |

| 19 | STEM NUT | ASTM A439 D-2 |

| 20 | BEARING GLAND | AISI 1020 |

| 21 | HANDWHEEL | ASTM A536 65-45-12 |

| 22 | LOCK NUT | AISI 1020 |

| 23 | BOLT | AISI 1045 |

| 24 | BEARING | GCr15 |

| 25 | BRACKET | ASTM A216 WCB |